Services

Where science meets practical application: the IAPK as an expert service provider.

Whether in the realm of powder metallurgy, ceramics or joining technology, we use our knowledge and technical equipment in each of our fields of expertise to benefit companies and end users by providing comprehensive advice and consulting, damage analysis and testing technologies.

We also offer our experience and expertise to projects underway in the field of industrial research. Do you have a commissioned project you would like to contract out? Feel free to contact us directly.

»Whether for the purpose of performing research or providing services, we have permanent access to the state-of-the-art technical equipment of our institute alliance.«

A broad spectrum:

our areas of service.

Are you interested in having us characterise a powder-metallurgical material, test a new component or examine a specific damage? The following is an overview of our areas of service at a glance:

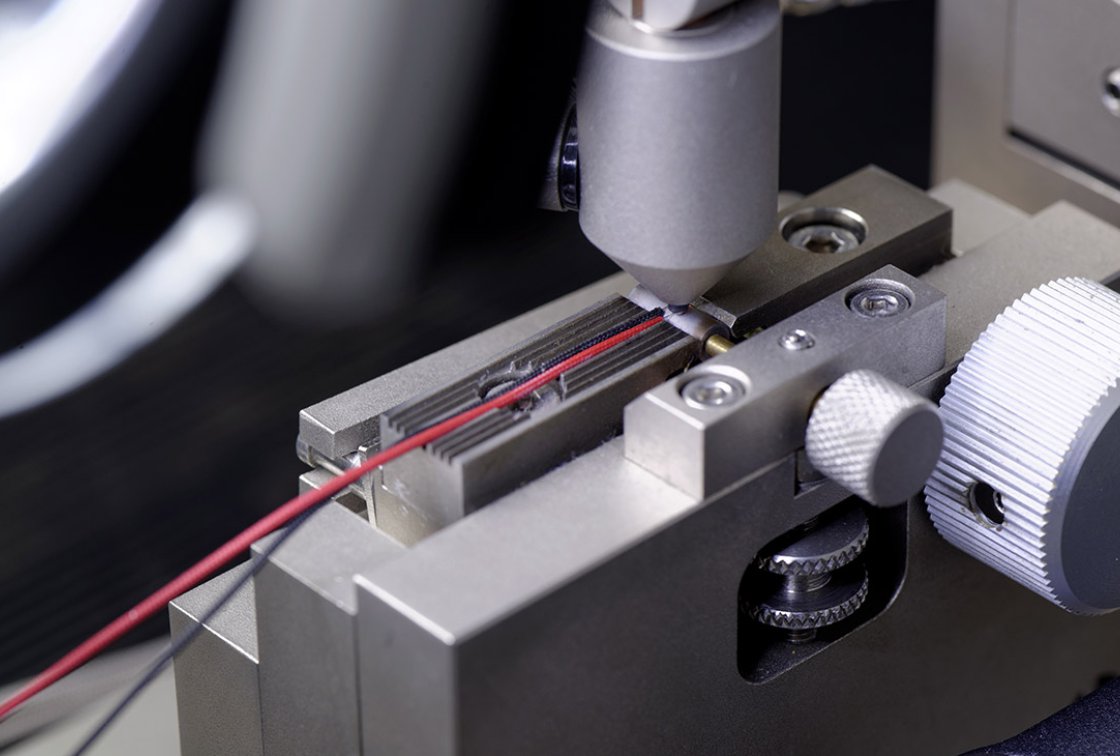

- Using a scanning electron microscope (REM/SEM) to assess fractured surfaces and identify the causes of fractures and fracture mechanisms

- Micro-hardness measurement – for example, to determine the hardening depth

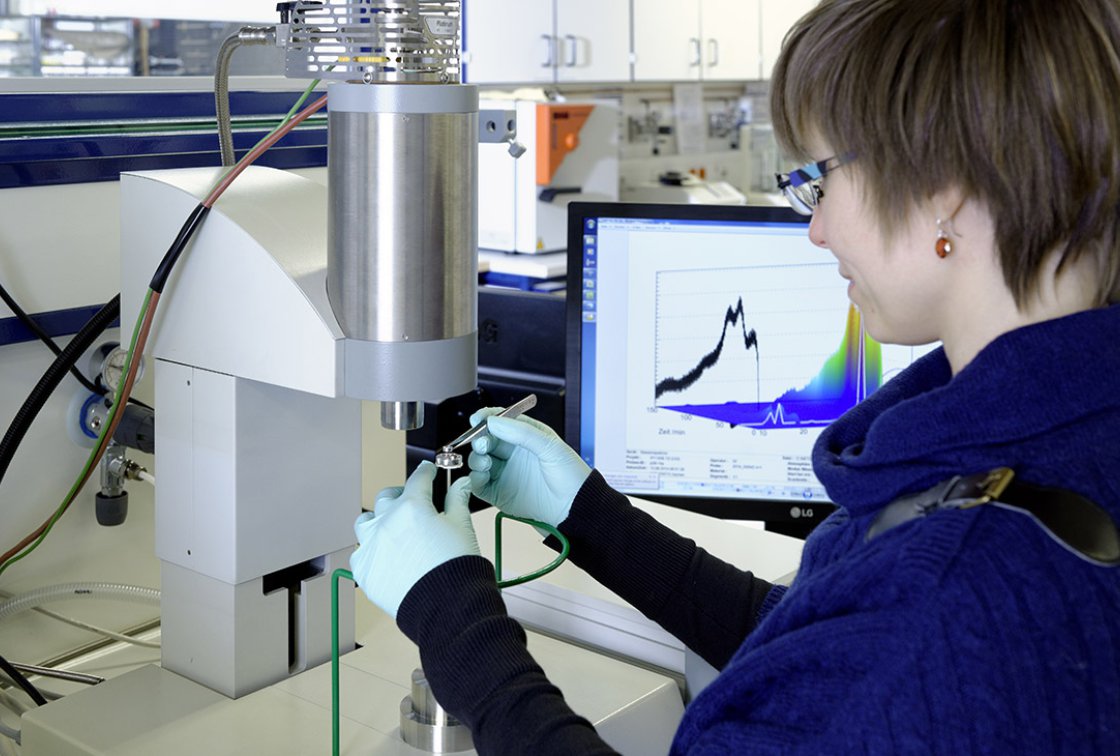

- X-ray residual stress analysis on metals and ceramics

- Measurement of elastic properties using the pulse excitation method (Grindosonic and IMCE)

- Residual stress measurements using a strain gauge (DMS)

- Colour penetration tests to detect cracks

- Tests to determine mechanical properties such as tensile strength, hardness, notched impact strength

- Tests to determine the fatigue strength in the LCF and HCF range

- Tests to determine the fracture-mechanical characteristics and crack propagation curves

- Roughness measurements

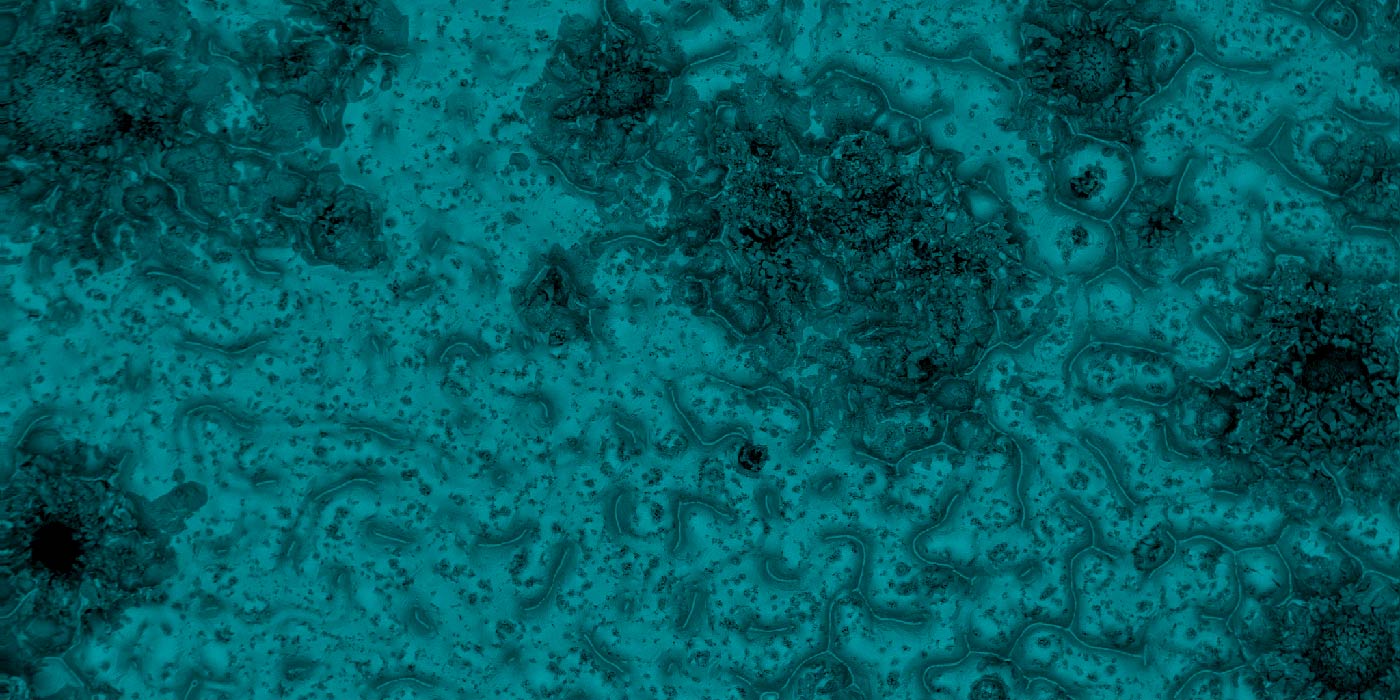

- Light-microscopic and scanning-electron-microscopic characterisation of materials (purity, microstructure, heat treatment, coatings, corrosion damage, etc.)

- Analysis of impurities, inclusions, foreign particles, corrosion products and residues by means of energy-dispersive X-ray emission analysis (EDX)

- Image analyses to determine porosities, densities, phase fractions, grain sizes, etc.

- Spectroscopic analysis of materials (OES, LECO)

- Density determination using the Archimedes method and helium pycnometry

- Determination of open porosity and pore size distribution using high-pressure mercury porosimetry (MIP)

- Qualitative and quantitative X-ray phase analysis, e.g. determination of residual austenite levels in steel

- Dilatometry to determine thermal expansion, sintering shrinkage, softening points, phase transformations etc.

- Determination of thermal conductivity using the Laser Flash method

- Calculation of thermal conductivity

- Dynamic Thermal Analysis (DTA) for determining thermally induced material changes

- Differential Scanning Calorimetry (DDK) to determine specific heat capacities

- Coupled emission gas analysis using Quadrupole Mass Spectrometry (QMS)

- Determination of transformation points (Ac1, Ac3, Ar1, Ar3, Ms, Mf)

- Creation of time-temperature conversion diagrams and time-temperature austenitization diagrams using a quenching dilatometer (DIL805A)

- Flow and creep curves, relaxation experiments as well as complex tensile/compression tests using a deformation dilatometer (DIL805D / T)

Additional services and areas of activity

Are you interested in gaining an overview of the quality characteristics and/or errors that have appeared in aluminium extrusion presses? We can help in this area.

Get where you want to go – faster: take advantage of our practice-oriented evaluation software for Wöhler fatigue testing.

Created in cooperation with industry, thus predestined for practical use

Summary of quality characteristics that have appeared and/or errors in aluminium extrusion presses

Extensive atlas with 237 pages describing 114 characteristics by means of 120 pictograms and 170 images in 13 categories

Each characteristic is portrayed in-depth, including a description of its impact and how to identify and recognise it, pictograms of how characteristics typically manifests themselves, a list of causes and how to fix and/or avoid these causes, targeted measures to eliminate and prevent certain characteristics as well as numerous pictures taken from actual practice that clearly show each characteristic

Can be used on all computers and with all operating systems

Easy to operate

User-friendly design with cross-references (links)

Flexible search function (including English names of the characteristics)

Index of characteristics featuring both German and English designations

Extensive bibliography

Opportunity to create high-quality printouts with images and pictograms

Target group:

- Management

- Production

- Quality control

- Sales

- Education and training

Reduction and processing of internal and external complaints

Helps to bring a new level of objectivity to discussions with customers (customer service guidebook/handbook)

Can be used for failure mode and effects analysis (FMEA)