The IAPK

Where theory meets practice:

the IAPK Institute.

Who are we? We are a team of highly qualified scientific and technical personnel who are passionately committed to the development and application of powder metallurgy and ceramic materials and components.

We carry out R&D, teach students and provide consulting services in these and related fields. As experts in the realm of testing technologies and damage analysis, we also work to solve problems brought to us directly by industry leaders and end users. Our activities are fostered even further by the alliance we form together with the Institute for Materials Applications in Mechanical Engineering (IWM) at RWTH Aachen University.

Knowledge transfer and networking

The IAPK team operates at the interface between scientific research and practical application. We maintain close ties to industry, ensure the rapid transfer of research findings and place great emphasis on networking. Indeed, we have found that this is the best way to foster advancements in all areas of powder metallurgy and ceramics, which is the ultimate purpose and goal of our institute and network. The IAPK works on a non-profit basis and is committed to promoting research, development and teaching as well as student education and training.

From powder to components:

our areas of expertise.

Our range of research, development and services encompasses all fields relating to powder metallurgical and ceramic material development and component manufacturing. This includes design and calculation, powder processing and shaping, consolidation via sintering processes, thermal processing and component testing. At the IAPK, we keep a watchful eye on the entire process chain.

»Design and simulation, powder processing and shaping, consolidation via sintering processes, thermal processing and component testing. At the IAPK, we keep a watchful eye on the entire process chain.«

Complex operating simulations

Our team places special emphasis on the joining techniques of ceramic structural components with metallic and other ceramic components. With the help of numerical simulations based on the Finite Element Method (FEM), we also generate lifetime predictions relating to specific operating conditions, whereby we validate the simulation of short- and long-term performance by means of mechanical experiments.

Our simulation models call for a multitude of mechanical and thermo-physical material data as well as application-specific test procedures, all of which require precisely the expertise the IAPK has to offer.

»Our range of research, development and services encompasses all fields relating to powder metallurgical and ceramic material development and component manufacturing.«

State of the art:

our technical equipment.

Whether for the purpose of performing research, fostering development or providing services, the IAPK offers permanent access to the state-of-the-art technical equipment of our institute alliance (IAPK and IWM).

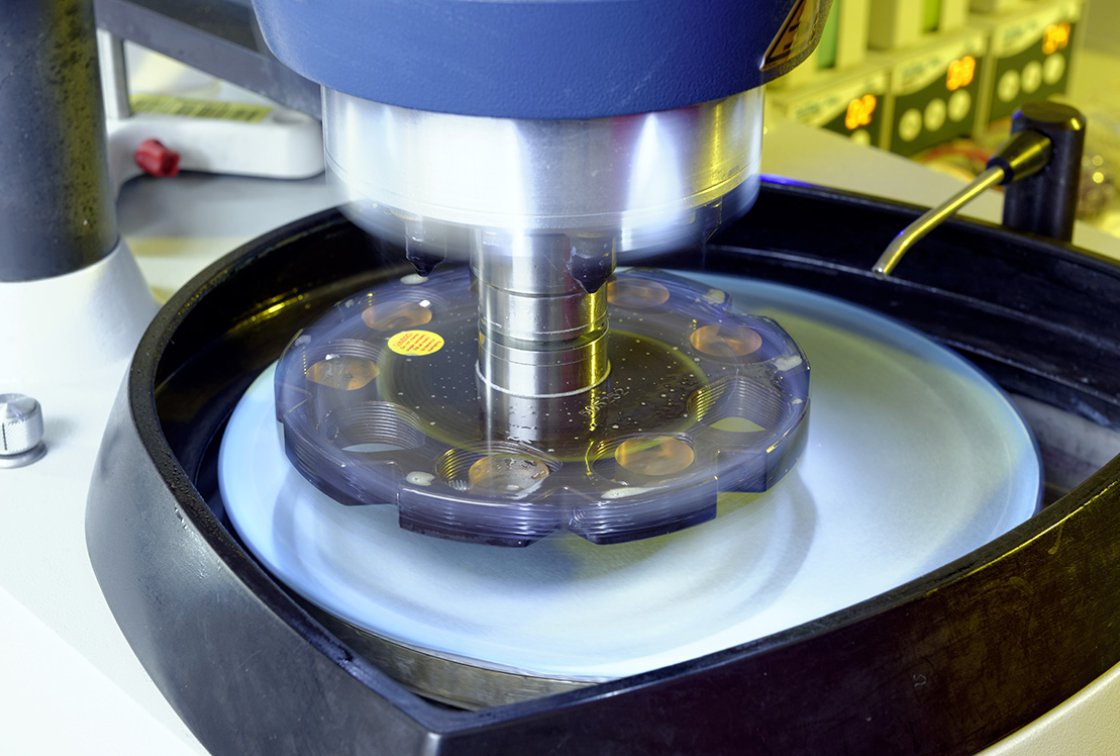

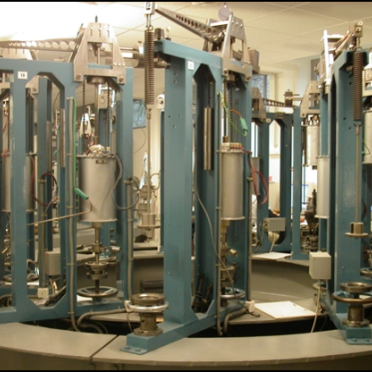

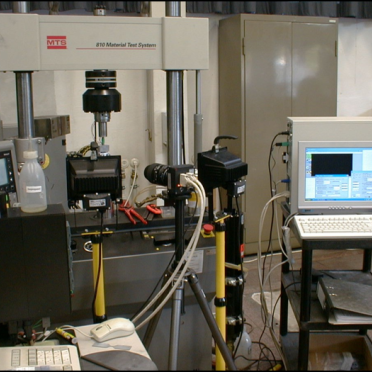

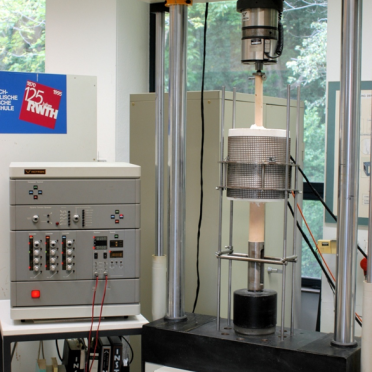

For example, for powder-metallurgical technology processes, we have various uniaxial presses, a cold isostatic press (CIP), a hot isostatic press (HIP), a unit for field assisted sintering (FAST), Laser powder bed fusion (LPBF) machine and numerous sintering furnaces. In our mechanical test laboratory, we have roughly 40 test rigs for the characterization of fatigue strength, as well as 25 creep test stands and various other testing machines.

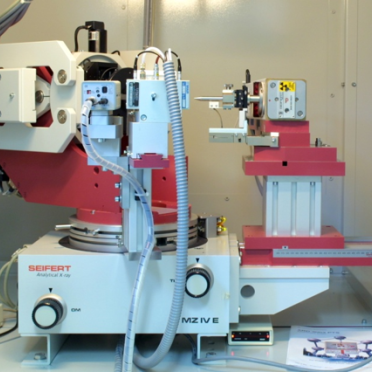

Light and scanning electron microscopy as well as a thermo-physical laboratory and X-ray diffractometry make it possible for us to characterise metallic and ceramic materials using modern test methods.

- Various light microscopes

- Scanning electron microscopy. Equipment: Jeol JSM 6400 with a BE detector

- Energy dispersive X-ray microanalysis (EDX). Equipment: Genesis 4000 from the line of EDAX Si(Li) detector

- Image analysis

- Mercury intrusion

- Micro hardness measurement

- X-ray diffractometer

- Laser granulometer for determining particle size

- 22 single-sample creep testing machines, maximum load: 12 kN, maximum temperature: 1000 ° C

- Servo-hydraulic universal testing machine MTS 810, Fmax: 100 kN, Tmax: 1000 ° C, Maximum haul-off speed: 500 mm / s

- high speed testing machine Zwick HTM 5020, Fmax = 50 kN; Tmax = 1000 ° C, maximum haul-off speed: 20 m / s

- Two servohydraulic testing machines Instron, Fmax = 50 kN; Tmax = 1200 ° C

- Schenck-Trebel electro-mechanical universal testing machine, type RMC 100, Fmax = 100 kN; Tmax = 1000 ° C, Max. Haul-off speed: 100 mm / min

- Universal testing machines for quasi-static loading at temperatures up to 1000 ° C

- Airflow mill

- Stirring ball mill

- Attritor mill

- Vibration mill, Retsch, with Al2O3 and WC grinding beaker

- Ball mills

- Rotational viscometer, Rheolab MC 10, computer-controlled (Physica)

- Uniaxial presses (up to 6t)

- Cold isostatic press (EPSI) up to 4000 bar

- Hot isostatic press

- LPBF machine (SLM Realizer 100)

- Vacuum inert gas furnace IBV (max 2200 ° C, N2, Ar)

- Corrosion tube furnace Ceram Aix, (max 1550 ° C, N2, O2, H2, etc.)

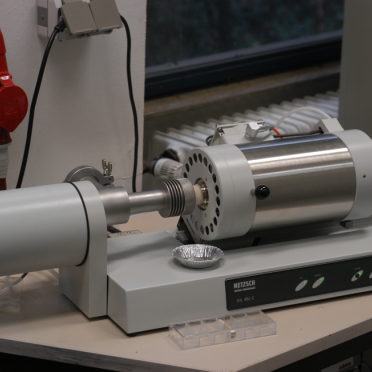

- LFA 427 (laser flash analysis)

- DSC 404 Pegasus (differential scanning calorimetry)

- E module test bench

- DIL 805A / D / T (quenching and forming dilatometry)

- DIL 402C (dilatometry)

From IPAK to IAPK:

the history of our institute.

Originally founded in March 1987 as the Institute of Ceramic Processes and Application Engineering (IPAK), we started off as an institute affiliated with the Institute for Ceramic Components in Mechanical Engineering (IKKM). Exactly four years later, in March 1991, we became an institute affiliated with the RWTH Aachen University by means of a mutually beneficial cooperation agreement. Professor H.R. Maier functioned as head of the IPAK until 2006. In 2008, after the merger of the IKKM with the Institute for Materials Science (IWK), which created the Institute for Materials Applications in Mechanical Engineering (IWM), the IPAK came under the leadership of Professor Christoph Broeckmann.

This merger also brought with it an expansion of our areas of expertise. Until then, the IPAK had focused entirely on ceramic-related issues, but now we extended our activities to include the field of powder metallurgy. In order to draw attention to this new focus among the general public, we changed our name in 2014 and have since been known as the IAPK – Institute of Applied Powder Metallurgy and Ceramics.

1987

The IPAK is founded as an institute affiliated with the IKKM and with Professor H. R. Maier as director

1991

Recognition of the IPAK as an institute affiliated with RWTH Aachen

2006

Fusion of the IKKM and the IWK to form the IWM

2008

Professor Christoph Broeckmann becomes director of the new IPAK/ IWM institute alliance

2014

The IPAK is renamed IAPK – to emphasise the institute’s expanded areas of expertise

What we stand for:

our values and goals.

The goal the IAPK is to make significant contributions to advancements in the realm of powder metallurgy and to carry out cutting-edge research in the mechanical behaviour of powder-technological materials and components. Our work is driven by our shared curiosity and a deep passion for knowledge. We are always pushing boundaries, and we enjoy leaving well-trodden paths to pursue new and innovative ideas.

»Our work is driven by our shared curiosity and a deep passion for knowledge.«

When it comes to new fields of research, we examine primarily the opportunities, but also calculate the risks. Of course, we adhere at all times to the principles of first-rate scientific practice and work lege artis”.

We document all of our research findings and regularly subject them to scrutiny. We maintain a policy of strict honesty with regard to contributions from partners and competitors, and we take consistent steps to prevent scientific misconduct.

Teamwork guarantees our success

We are highly aware that our motivated and highly qualified staff is our most valuable resource. In order to be able to make their own unique contributions to the positive development of our institute, we encourage each member of our staff to think freely and independently and to work with an entrepreneurial spirit.

We use key figures as a tool for performance-oriented leadership. We also work both internally and externally in a customer-oriented manner and regularly involve suppliers in the ongoing improvement of our activities.

With passion and expertise:

our team.

Day after day, the team of highly qualified scientists and technical staff at the IAPK work with a great deal of passion and commitment on the development and application of powder-metallurgical and ceramic components. Find out more about our team!

Careers at the IAPK.

There are no positions open at the moment.

Contact partners:

Institute of Applied

Powder Metallurgy and Ceramics

at RWTH Aachen e. V.

Dr.-Ing. Anke Kaletsch

Augustinerbach 4

52062 Aachen

T: +49 (0)241 / 809 55 34

info@iapk.rwth-aachen.de