Carbide additivation of PBF-LB tool steels with functional polymer binders

Development of a process for carbide additives on tool steel powders using a functional polymer binder to improve the processability, microstructural isotropy and strength of hard iron alloys

Motivation

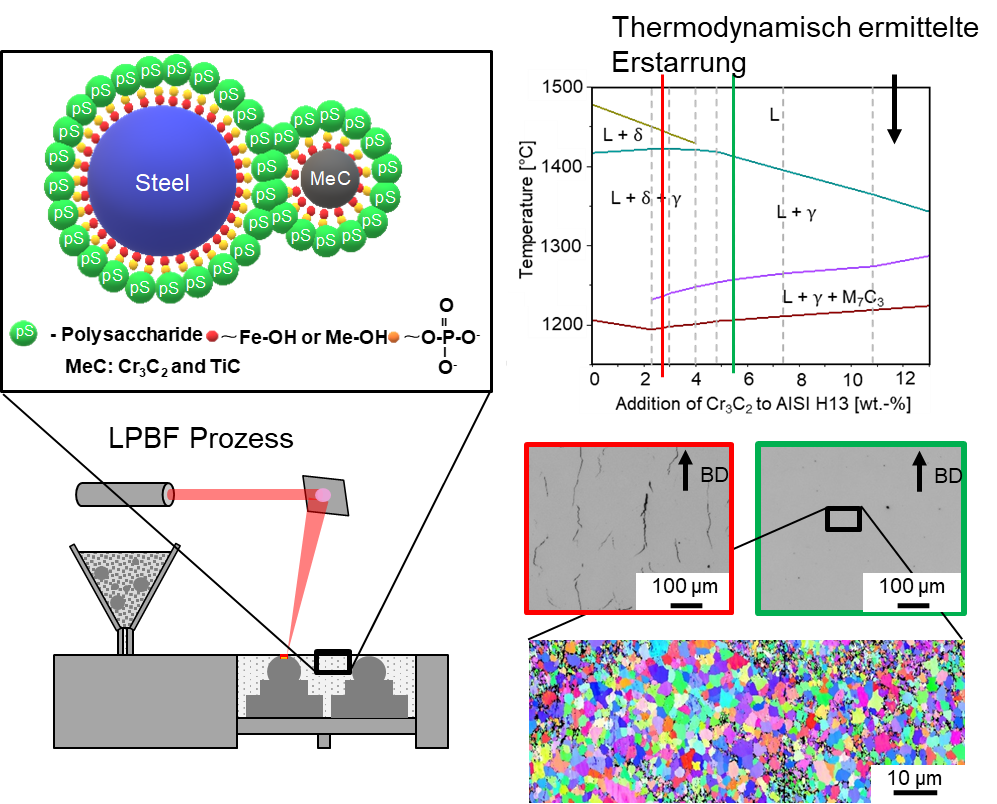

While pre-alloyed powders for additive manufacturing seem to be limited in their alloy content due to cracking, the alloy content can be increased by using differently prepared feedstocks. Particle-reinforced alloys are being investigated to broaden the range of alloys that can be processed. Carbides added to the powder feedstock, which act as solidification nucleation sites, are expected to increase isotropy, reduce hot cracking and improve mechanical properties. To prevent segregation in the powder, polymer-based binders are used to ensure that the carbide particles stick to the steel base powder.

Objectives

The aim of the project is the additive manufacturing of carbide-rich iron alloys with reproducible, homogeneous and isotropic microstructures and good mechanical properties.

Project Contents

The alloys are developed by thermodynamic equilibrium and Scheil-Gulliver solidification calculations. The investigation includes the influence of "satelliting" on the rheological and thermophysical powder properties. Multi-scale microstructural investigations and static and dynamic mechanical tests characterize processability through LPBF, microstructure formation, and the benefits of an isotropic microstructure on mechanical properties. Grain size and microstructure become important indicators of the project’s success.

Project partner

Leibniz Institute for Interactive Materials (DWI)

Funding

Funded by German Research Society within SPP 2122: Materials for Additive Manufacturing